Project Introduction

Location:Heilongjiang province ,China

Project Name:ORing Enhances Management Efficiency of China's Daqing Oil Field

Products Deployed:IGS-9084GP, IES-3240, IES-1160, IES-1080A

Project Requirement

- Reliable data transmission

- Resistance to harsh environments

- Simplified management and real-time monitoring capabilities

SolutionDaqing oil field is China's biggest and the world’s 10th largest oil field. Located in Heilongjiang province, the oil field produces 40-50 million tons of oil every year. With an area of 6000 square kilometers, the oil field consists of 48 oil and gas fields of varied scales, including those in Sartu, Xingshugang, and Lamadian. The drilling sites are mainly located in the northwest and northeast of the field, covering 14 basins.

In late 2017, ORing started to provide network communications systems and PLC control systems for the Daqing Oilfield Company. In April 2018, ORing became a qualified network device supplier to the oil field.

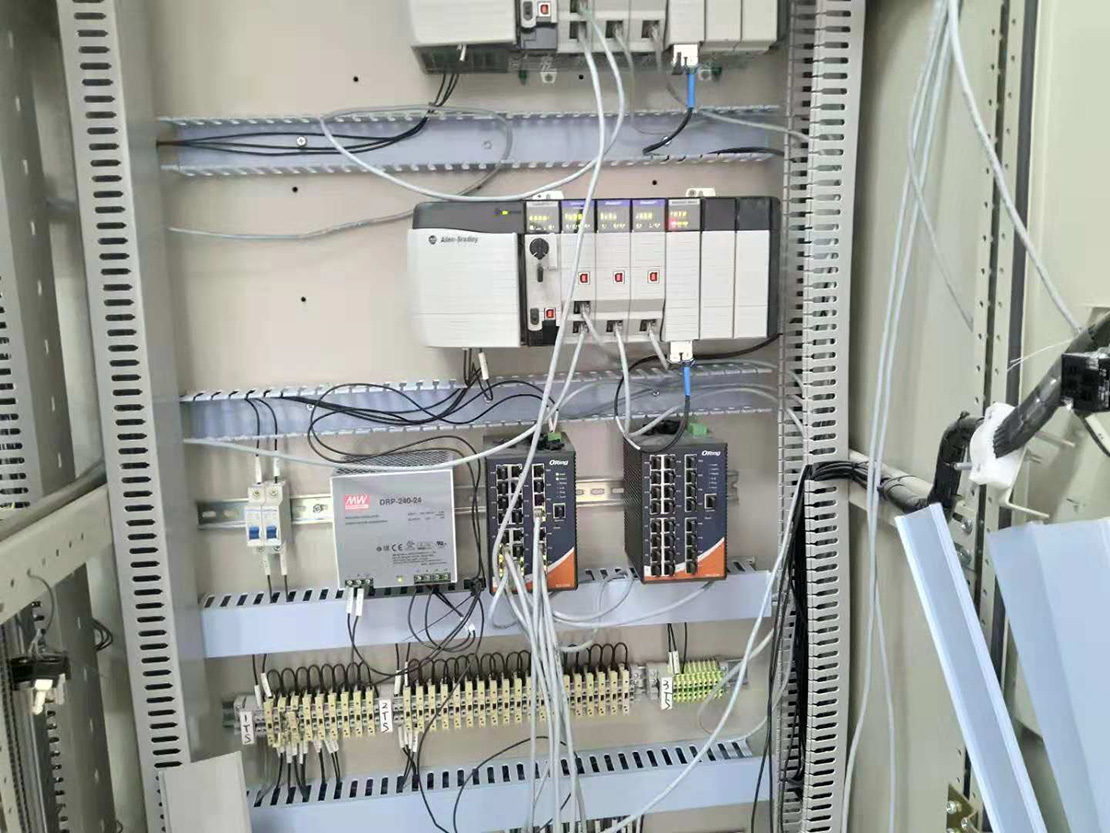

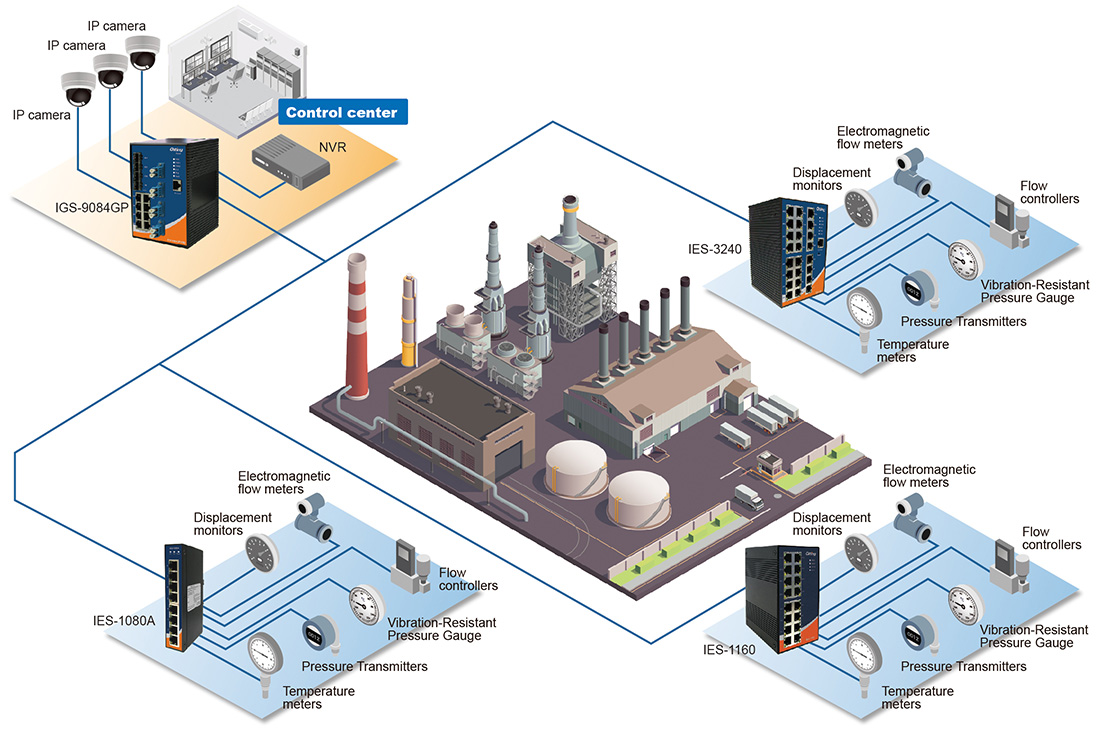

An oil field joint station is where multiple processes take place such as separation of multi-phase fluids, crude oil dehydration, crude oil stabilization, measurement of oil, water injection, waste water treatment, natural gas processing, and oil transport. The control system at the station usually collects data from sensors and all kinds of instruments through PLCs. Data related to temperature, pressure, fluid level, flow, oil-water interface, flammable gas, and valve is transmitted to the control center over an industrial Ethernet network, allowing the staff to monitor the data in real time. Based on the environmental conditions of the control center and control rooms, the customer has installed different kinds of industrial Ethernet switches provided by ORing.

The IGS-9084GP is used as an aggregation switch to transmit data from control rooms to the control center. With a full-Gigabit set-up, the IGS-9084GP can provide sufficient capacity for bandwidth-hungry devices such as cameras and NVRs. The IGS-9084GP also supports ORing’s Open-Vision management software which allows for central management and configuration of all switches. The customer can thus monitor network operations more efficiently.

In each control room, the IES-3240, IES-1160, and IES-1080A unmanaged Ethernet switches are used to address various needs. The high port density of the IES-3240 enables the connection of a wide range of devices such as electromagnetic flow meters, flow controllers, pressure gauges, displacement monitors, and temperature meters. All of these switches support DIN-rail installation, alongside a wide operating temperature range, compliance with industrial standards, and a five-year warranty.

With ORing’s networking solution, the customer has built a reliable data communications network, ensuring data from each device is transmitted to the control center in real time without data loss, thus achieving uninterrupted operations.

System Structure

Why Oring

- Comprehensive networking solutions for industrial applications

- Industrial-grade design including an operating temperature range between -40 ~ 70℃ and a 5-year warranty

- Open-Vision software with real-time monitoring capabilities for higher management efficiency

- Abundant experience and achievements in industrial applications